Quick and Easy to Set Up

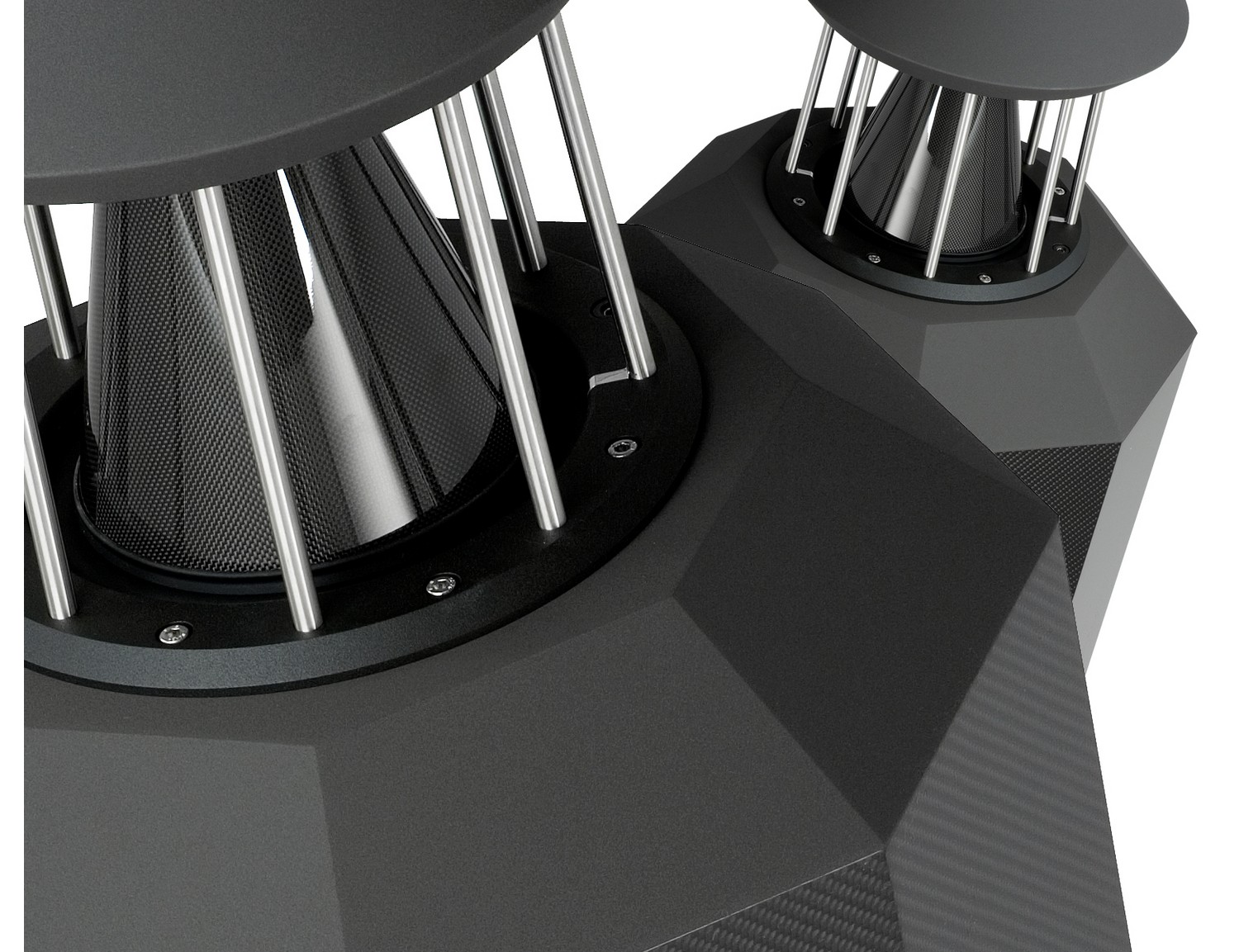

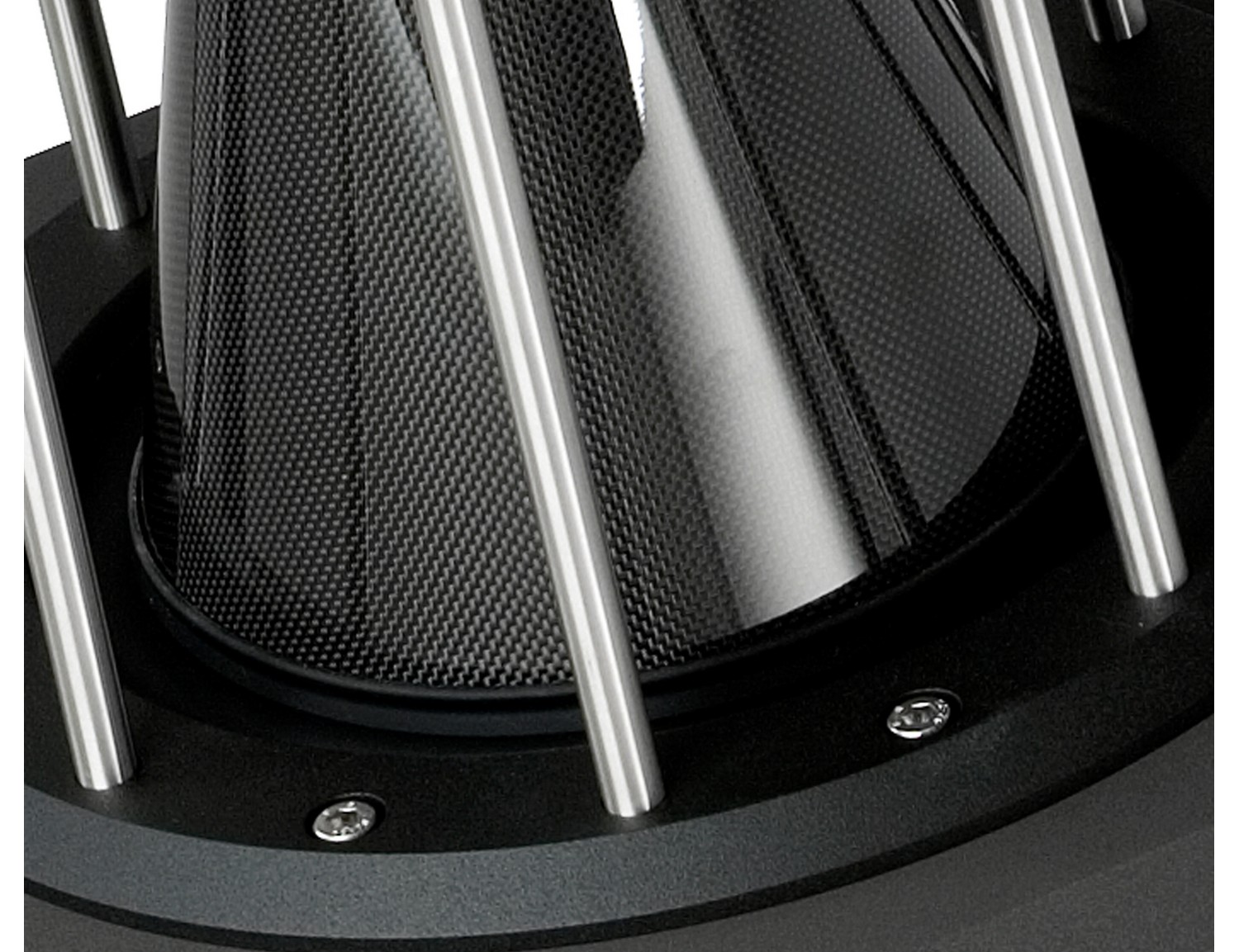

The DDD driver’s omnidirectional radiation pattern and wide operating frequency range make the Carbon MK IV less critical of positioning in the room than conventional loudspeakers, so they are usually very quick and easy to set up. In addition, because the Carbon MK IV is omnidirectional, there is no toe-in adjustment to worry about, which is one less variable to deal with on set-up.

The Carbon MK IV will drive rooms up to 90 square metres (950 sq ft) in size, yet the footprint is a modest 404mm x 404mm (15.9” x 15.9”). It can also work well in smaller rooms. We have successfully used them at shows in rooms as small as 285 sq ft (27 square metres), but as with any loudspeaker, we always recommend a home demonstration before you make a final choice.

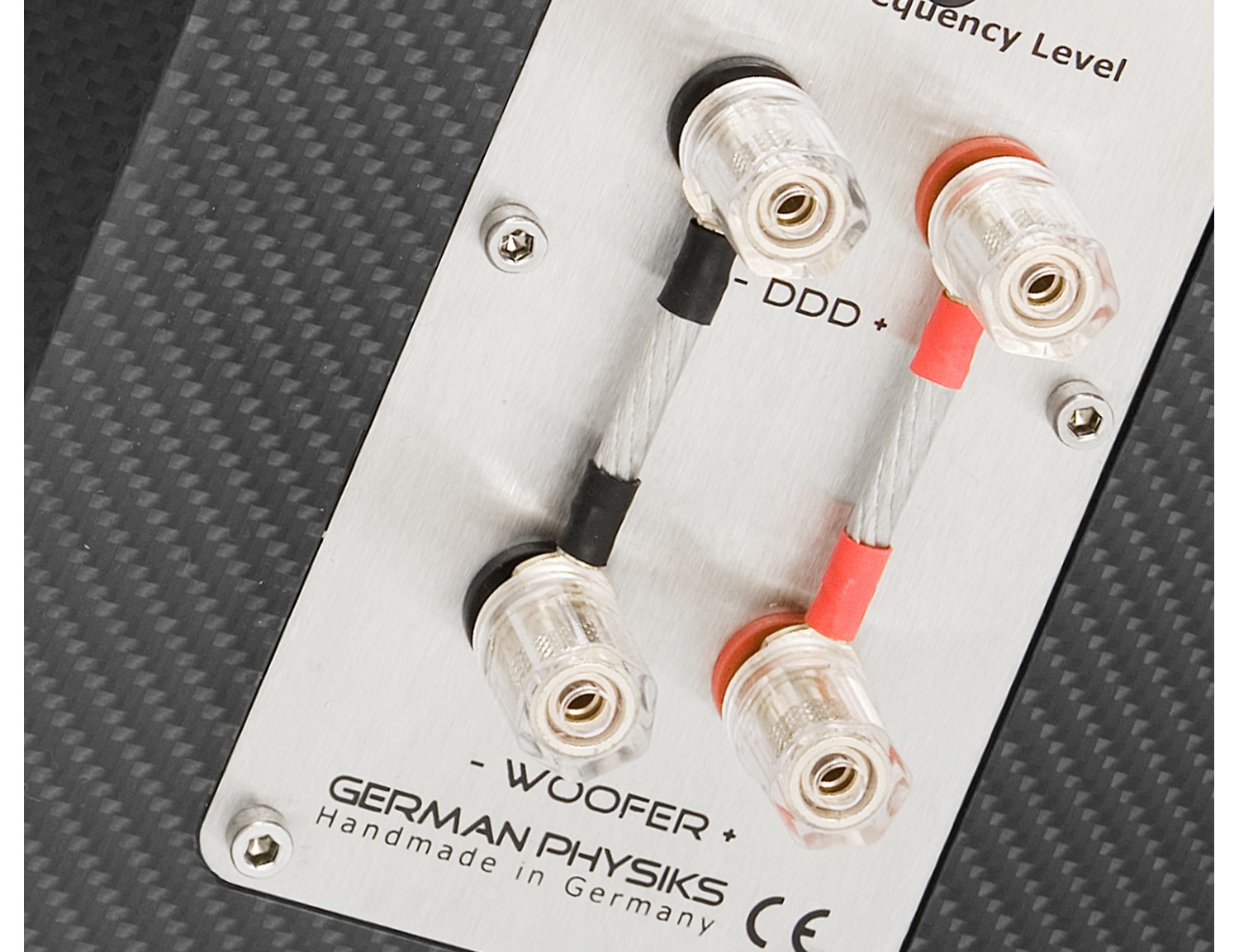

High quality Input Terminals

Two sets of high quality WBT nextgen™ loudspeaker terminals are fitted allowing the Carbon MK IV to be bi-wired or bi-amped. High quality jumpers are supplied to enable the loudspeaker to be used with just one set of loudspeaker cables.

Adjustable High Frequency Output

Jumpers on the rear panel allow the high frequency output level to be adjusted in 4 steps: -2dB, flat, +2dB and +4dB. This allows the user to easily compensate for the variations in the absorption of high frequencies that occur due to different types of furnishings and room constructions.

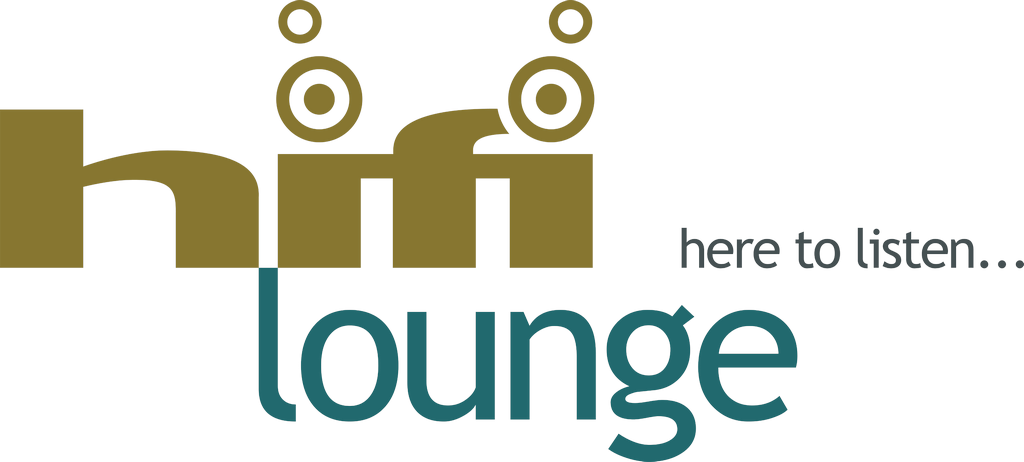

Low Resonance Cabinet Design Enhances Transparency

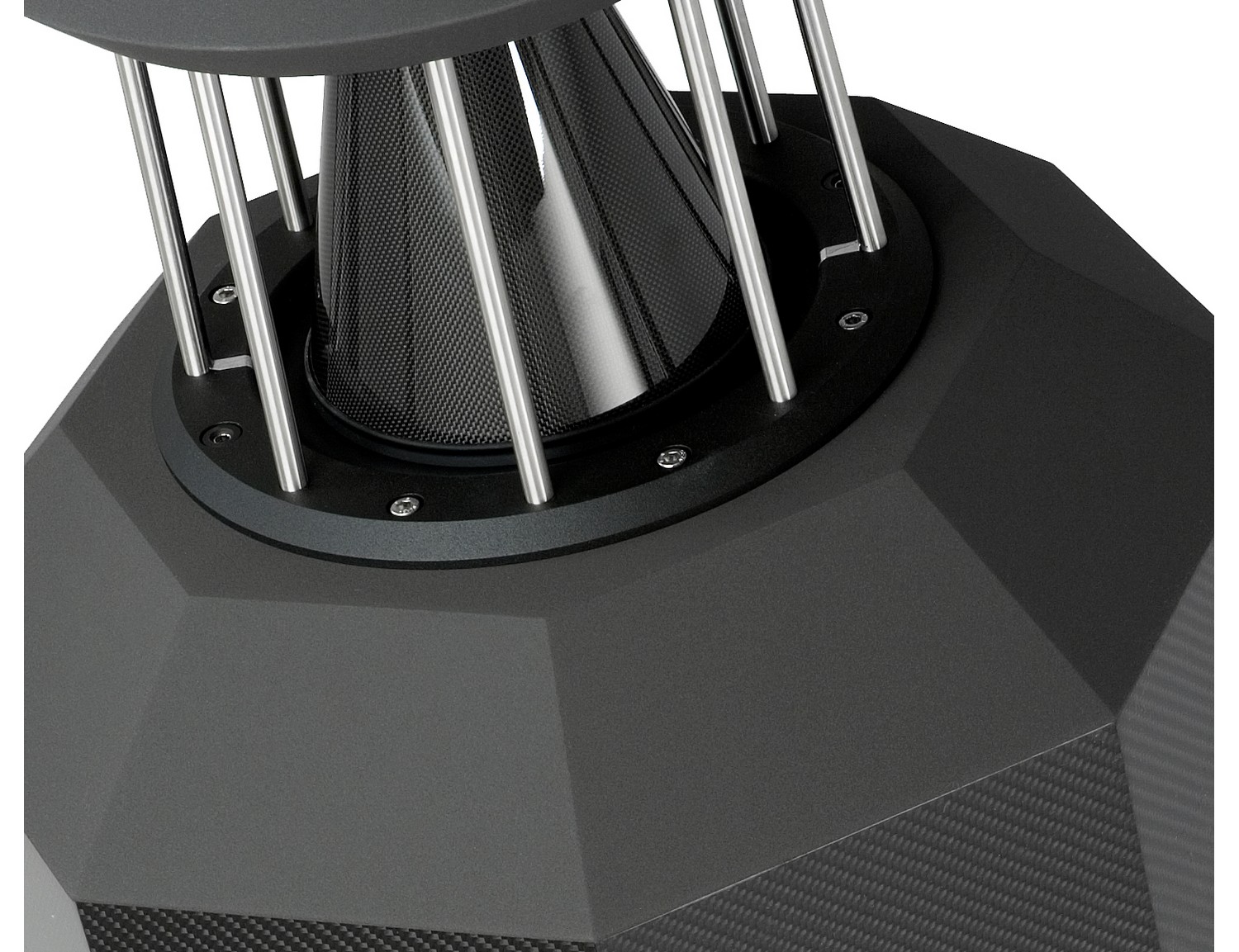

The Carbon MK IV uses an octagonal cross-section cabinet constructed from heavy panels of MDF, with re-enforcements fitted to critical points within the structure. The use of an octagonal cross-section allows the individual panels to be made smaller and therefore stiffer than they would be if a conventional square or rectangular cross-section were used. This construction minimises the colouration caused by cabinet resonances, which would otherwise degrade the loudspeaker’s ability to resolve fine detail and so reduce its ability to produce a sense of realism.

Residual resonances are minimised by applying a special damping material called Hawaphon® to the inside of each panel.

Hawaphon® is a polymer sheet containing a matrix of small cells filled with very fine steel shot and was originally developed as an anti-surveillance measure for use in military and government buildings. It adds mass to the panel to reduce the resonant frequency and the ability of the shot in each cell to move against each other provides a very effective way of converting vibration energy into heat. Hawaphon® achieves a broadband attenuation of structure-borne sound of more than 50dB, which is a remarkably high figure.

Finally, to damp resonances of the air within the cabinet, the whole of the inside of the cabinet is lined with a thick layer of high-density felt.