Products

Stax SR-X9000 Electrostatic Earspeakers

£5,195.00

What HFL Thinks

Stax SR-X9000 Electrostatic Earspeakers – At HFL we couldn’t be happier to offer Stax headphones, or Earspeakers as they are better known, to our customers. If you want the best headphone experience you really do need to hear a Stax system, being an electrostatic design the level of detail is quite stunning, as is their agility and musicality. A Stax system really does stand out from the crowd and is considered by many to offer the pinnacle of what is possible with a headphone system. We have a selection of Stax systems on demo so please feel free to come in to HFL to experience something a little different.

Flagship model with new fixed electrode MLER-3

Genealogy of X, gene of Ω

Ideal form of electrostatic ear speaker. A fixed electrode that reduces the effects of air resistance and reflection and ensures high sound transmission. That vision was already found in the metal mesh electrodes of the SR-X, which was launched in 1970. Then, in the 90’s, Stax once again challenged his dream of metal mesh electrodes with SR-Ω. However, mass production of large metal mesh electrodes mounted on SR-Ω was extremely difficult due to the difficulty of manufacturing them. This is the reason why SR-Ω has been produced in small quantities while maintaining high quality sound quality.

After that, Stax continued to manufacture the Lambda series, which continues to this day, and also developed the SR-007 series, which adopted a circular unit. In 2011, we released SR-009, which is the foundation of the current flagship model. Until now, we have been making products without stopping. The development perspective and manufacturing technology gained during that time became indispensable for the future development of Stax products.

Now, ideas that were difficult to realize with SR-X and SR-Ω are about to become reality with the idea of new manufacturing technology and development. Large metal mesh electrodes revived in modern times, products suitable for releasing their capabilities. That is the new flagship SR-X9000 that surpasses SR-009S.

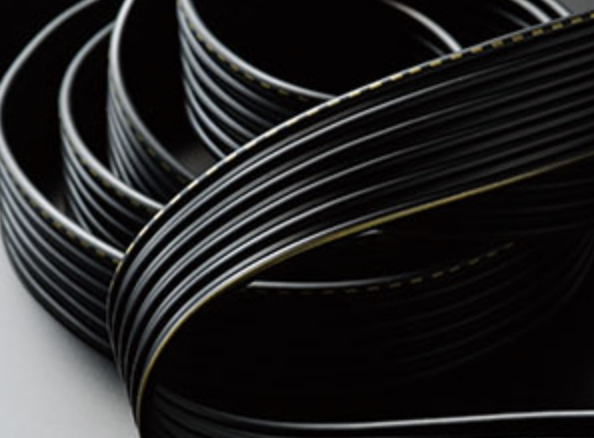

Evolution to “MLER-3” It has been more than 20 years since the appearance of SR-Ω. During that time, in addition to improving the accuracy of metal mesh manufacturing, the manufacturing know-how of multi-layer fixed electrodes cultivated during the development process of SR-009 became a major driving force for the birth of SR-X9000. The “MLER-2” mounted on the SR-009S has evolved into a 4-layer structure “MLER-3” in which a mesh electrode and a conventional etching electrode are newly crimped by thermal diffusion coupling. The manufacturing technology of multi-layer fixed electrodes, which has matured through the two-generation flagship model, has made a great contribution to the stable mass production of large metal mesh electrodes. “MLER-3” has both rigid characteristics that are strong against resonance while smoothly evolving the sound transmission characteristics compared to the conventional multi-layer fixed electrodes. Thoughts on metal mesh The circular metal mesh mounted on the SR-X was one of the ideal designs as an electrode that reduces the effects of air resistance and reflection and enhances sound transmission. However, if the size and thinness of the metal mesh electrode are pursued for sound quality, the strength will be insufficient and resonance will cause the reproduced sound to become muddy, so there was a big hurdle to install it in the product. The SR-Ω, which was developed again in the 1990s as a product equipped with a metal mesh, aimed to increase the size of the metal mesh, so at the same time, it was necessary to perform high-precision work of reinforcing the mesh surface with delicate manual work using an adhesive. Requested. For this reason, the manufacture of SR-Ω metal mesh electrodes was extremely difficult, and stable mass production was not possible. This is the reason why only a small amount of SR-Ω was released to the world while achieving excellent sound quality. Diaphragm that is 20% larger than the previous flagship Adopted a diaphragm made of ultra-thin super engineering plastic film. By reducing the mass as close to zero as possible, excellent transient characteristics have been achieved, and sound followability has been improved from low to high frequencies. The diaphragm area has succeeded in increasing the diameter by 20% compared to SR-009S, and has acquired a vast sound field that breaks the limits of headphone listening. Machined aluminum housing that eliminates unnecessary resonance The main body that houses the sounding unit uses a machined aluminum housing that is tough. Adopted a new design that firmly fixes the sounding unit and thoroughly eliminates unnecessary resonance of the housing itself. The flow of sound waves from the sounding unit has been made smoother, and the acoustic characteristics inside the housing have been improved. Tilt guard mesh structure The guard mesh installed parallel to the sounding body produces many direct reflections that affect the hearing of the sound. In order to solve this problem, SR-X9000 adopts a strut structure with different heights in the front and rear to change the height of the gap between the sounding body and the guard mesh. As a result, the guard mesh is not parallel to the sounding body and controls the reflection angle of the sound. We have acquired clearer sound quality that is not affected by unnecessary reflected sound. With adjust click ・ Stainless steel arc assembly Stainless steel is used for the arc assembly We have increased resistance to twists and twists, aiming for a more stable listening fit. In addition, the “I” type aluminum stabilizer installed on the top of the arc suppresses the resonance of the arc itself and reduces the return of unnecessary vibration to the sounding unit. Genuine leather is used for the head pad that comes into direct contact with the head. The position can be adjusted with an adjuster that has a 9-step click mechanism. Genuine leather ear pads with excellent breathability and fit Genuine leather (sheepskin) with excellent breathability and flexibility is used for the ear pads. You can keep the proper contact between the ear speaker and the head for a long time, and you can fully experience high-quality low-frequency expression and fresh sound quality. It also contributes to reducing fatigue and comfortable listening for a long time. Original wide low-capacity cable with a hybrid structure of high-purity 6N-OFC + silver-plated annealed copper wire 6N OFC high-purity annealed copper wire (φ0.14 × 3) with excellent low-frequency reproduction is used for the center line, and high frequencies are used on the outer circumference. Placed silver-plated annealed copper wire (φ0.08 × 9) with high characteristics. Adopts Stax’s original wide 6-core parallel. Re-cable compatible Uses a replaceable cable mechanism. It enables future support for high-quality cables and easy maintenance against unexpected disconnections. Includes two cables with 2.5m and 1.5m specifications that can be exchanged according to the listening style. In addition, based on ergonomics, the cable mounting part does not face vertically downward, but by providing an angle in the front, it has the effect of reducing the mounting burden during listening due to the weight of the cable itself. Paulownia storage case “paulownia wood” is used for the storage case. It has low heat conduction and excellent humidity control effect, and provides optimum storage conditions for ear speakers. Specification

You may also like…

-

Stax SR-009S Electrostatic Earspeakers Our price: £3,895.00

-

Stax SRM-T8000 Hybrid Reference Energiser Our price: £4,395.00

-

Trilogy H1 Energiser For Electrostatic Headphones From:£6,250.00

Reviews

There are no reviews yet.